GETEC is committed to provide customers with high end benchmarking, duty cycle development, calibration and vehicle drivetrain integration services. Additionally, GETEC offers issue resolving service in the product development process.

GETEC has extensive engineering service experience in the field of vehicle and powertrain.

GETEC has years of calibration experience. By hardware benchmarking, GETEC is capable of analyzing the powertrain structure and its layout in the vehicle, component dimensions and materials, as well as their functionalities within shortest time. For driving evaluation, it is necessary that GETEC professionals drive the vehicle in all possible conditions. The measurement data evaluated to generate for example shift maps or different accelerator pedal maps.

-

Measurement Tool Integration

Vehicle CAN Signal Decoding

Diagnostic Signal Integration

Additional Signal Integration

-

Drive Quality Analysis

Drivability Assessment

Performance Evaluation

Energy Consumption & Emissions Testing

-

High Level Calibration Analysis

Pedal Maps

Pedal Range Layout

Number of Pedal Maps Used

Recuperation Map

Evaluation

-

Middle Level Calibration Analysis

TCU – Shift Control

Power on Different Shifts

Torque Increase/Decrease

Mode Switching

Engine Start/Stop Strategy

-

Low Level Calibration Analysis

Hydraulic Behavior of Different Condition

Temperature Influence

Functional Control

Self-learning

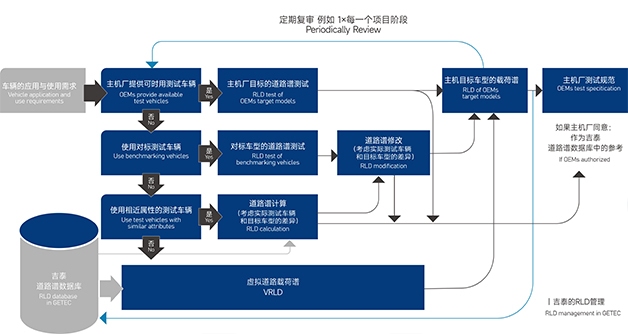

Virtual RLD (VRLD). VRLD – as the name implies – uses virtual simulation or calculation in combination with an existing RLD database, to expand the results into applications, which do not have existing RLD measurements. By applying the VRLD big data, the analysis is not limited to the real RLD testing and environment anymore. VRLD expands the usage of RLD to virtual driving environments, driving profiles and customers.

-

01 RLD Plan

Target setting

Measurement location & content planning

Definition of required measurement signals

Driver characteristic planning

-

02 RLD Preparation

Vehicle preparation

Sensor installation/CAN decoding by GETEC’s DecodeIT tool

Vehicle approval

Vehicle logistics

-

03 RLD Acquisition

RLD measurements on real road

Test on proving ground

RLD Test in special environment or locations

-

04 RLD Evaluation

Duty cycle development

Test bench test cycle development

Vehicle test program development

Test specification development

FOR MORE DETAILED INFORMATION, PLEASE CONTACT OUR TEAM.

WE WILL GET IN TOUCH WITH YOU AT OUR EARLIEST CONVENIENCE UPON RECEIVING YOUR MESSAGE.

-

EUROPEAN MARKET

Michael Spielmann

Key Account Manager

+49 2464 90266 266

michael.spielmann@getec-gmbh.com

-

ASIA MARKET

Jie Cao

Vice General Manager | Solution BU

+86 512 6292 8086

Jie.cao@getec-gmbh.com