GETEC Technology Empowerment | Decoding the Secrets of Cost Control in E-Drive Development

While automakers pursue high efficiency and reliability in e-drive systems, cost control becomes a key determinant of market competitiveness. Through meticulous teardown analysis and benchmarking, GETEC helps automakers achieve deep optimization of cost structures without compromising performance—ensuring every investment precisely enhances product capabilities!

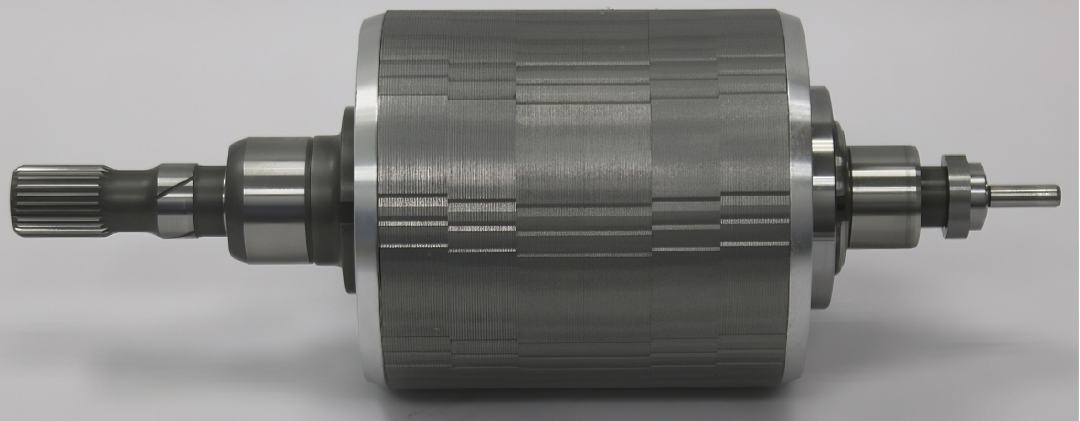

GETEC E-Drive Teardown: Systematic Insights from Structure to Cost

- Full-Chain Component Teardown: Integrated analysis of motor, electronic control, and reducer to identify redundant designs and over-specified components.

- Cost Drivers Mapping: Correlate technical parameters with BOM costs to pinpoint "high-cost, low-return" elements.

- Lightweighting and Integration Proposals: Offer structural simplification and material substitution solutions based on competitors’ modular designs.

- Client Achievement: One automaker reduced unit costs by 12% through electronic control system integration optimization, with zero compromise on performance!

Transforming Teardown Data into Cost Advantages

01. Cost Reduction in Electronic Control Systems

- Industry Pain Point: IGBT modules and cooling systems account for disproportionately high costs.

- GETEC Solution: Benchmark localized chip solutions and efficient cooling structures to achieve cost optimization.

02. Innovation in Motor Materials

- Industry Pain Point: High price volatility of rare-earth permanent magnet materials and supply chain risks.

- GETEC Solution: Recommend non-rare-earth alternative materials and optimized winding processes to balance performance and cost.

03. Compact Reducer Design

- Industry Pain Point: Complex multi-gear reducer structures lead to escalating manufacturing costs.

- GETEC Solution: Adopt leading competitors’ single-gear and integrated housing designs to reduce weight and cost.

Why Automakers Choose GETEC?

- Data-Driven Decision Making: 90% of teardown conclusions directly guide procurement and design iterations.

- Cross-Vehicle Platform Compatibility: Supports modular transplantation, reducing new model development cycles by 15%.

- Proven Practical Results: Has helped clients achieve an average cost reduction of 10% while maintaining industry-leading performance metrics.

Make Every Dollar Spent Create Tangible Value for Users—Start with GETEC E-Drive Teardown!